Telephone

18660980818

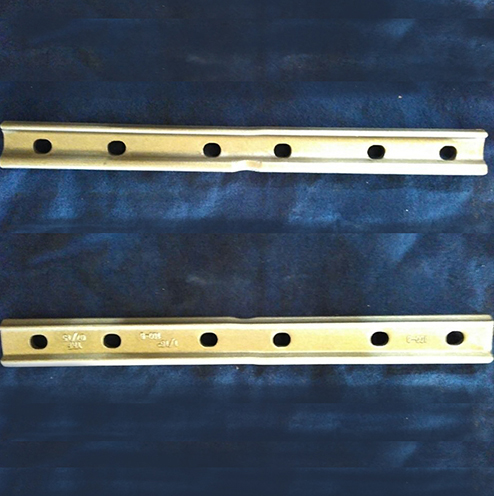

Although forgings and forgings belong to forgings, their processing methods are different. Forging parts are precisely forged by a press driven by switched reluctance servo motor. The forgings have small tolerance, follow-up grinding only, complete fiber structure and high strength. Forging parts are forged by air hammer or press in red hot state.

In terms of performance, forgings have compact processing structure and good mechanical properties. Forging process can ensure the continuity of metal fiber structure, make the fiber structure of forgings consistent with the shape of forgings, complete metal streamline, and ensure that parts have good mechanical properties and long service life.

Die-splitting forging technology can be used in the forming of forgings, because its economic effect is obvious. Some of the metal consumed on the flying edge in die forging of common forgings can reach 15%-30%. After changing to die-dividing forging of forging parts, the material is generally reduced. Utilization ratio can be 25%-70.50%-85% for common die forging.

This not only reduces or eliminates the flying edge, does not use the die forging inclination or the very small die forging inclination, tolerance, allowance and dressing, but also makes the forging shape as close as possible to the shape of the parts, so that the cutting amount can be reduced by 40%-60% due to the refinement of the shape and size of the forgings, thus the energy consumption can be reduced a lot.

In addition, the parting die forging of forging parts requires precise blanks, and the forming process can be completed in one process, thus eliminating the pre-forging process of common forging parts, thus reducing the number of forging steps and increasing labor productivity by 25%-50%. Because there are few forgings without flying edges, it is easy to realize the mechanization and automation of forging process.

Die Forging Manufacturer, Truck Front Axle, Large Die Forging Selection Linyi Hongsen Rail Transit Material Co., Ltd.