Telephone

18660980818

Obvious leakage can be found by visual inspection when small cracks are not easy to find. Oil immersion method can be used to check, that is, first clean the cylinder block die forgings, then wipe them with kerosene-soaked cotton yarn in the measured part after drying. When the forgings are processed, kerosene will soon leak out from the oil-leaking part. If white powder (or red powder) is applied on the outside, the size and shape of the crack part will be changed. More obviously, it can also be inspected by hydraulic method, that is, the cylinder block die forgings are loaded with cylinder cushion and cylinder head, and all the holes are closed except for a small hole connected with the water pipe of the hydraulic press. Then, the holes are installed on the test bench, the hydraulic press switch is turned on and the leakage can be determined for 3 minutes under 250 kPa pressure.

Small cracks in cylinder block die forgings can be bonded by gluing method, that is, five parts of 301 glue (or 502 glue), three parts of iron powder and two parts of copper powder are mixed into paste and applied to cracks or sand holes. It can be used after 20 hours. Hefei die forgings with large cracks or sand holes should be welded and repaired. First, the cylinder block die forgings should be cleaned, the cracks are air-dried after pickling, and then the cylinder block die forgings should be preheated to 80 hours. ~ 120 degrees Celsius.

Then use phosphorus bronze welding rod to weld and repair, if the crack or sand hole is bigger, it can also be repaired by plate or riveting. For honeycomb sand hole, the standard of die forging processing can be filled with epoxy resin. Three parts of ammonium ethylene, one part of epoxy resin liquid can be mixed and smeared into the inner cavity of the cylinder block die forging. After 24 hours of consolidation, it can be put into use after water pressure test.

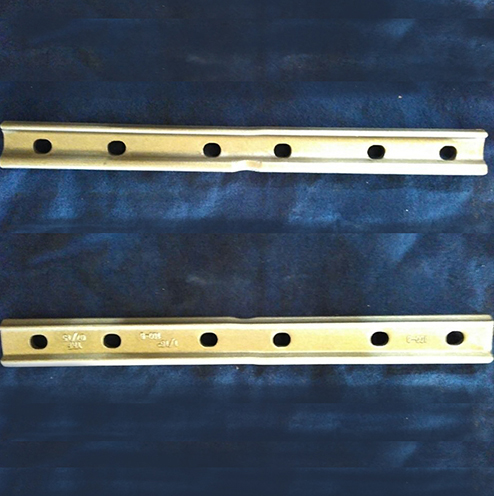

Die Forging Manufacturer, Truck Front Axle, Large Die Forging Selection Linyi Hongsen Rail Transit Material Co., Ltd.