Telephone

18660980818

In the design of die forgings, the selection of parting surface should follow certain principles. First, all or most of the die forgings should be located in the same sand mould, or the main processing surface and the processing reference surface should be in the same sand mould, so as to prevent mistake, ensure the dimensional accuracy of the castings, and facilitate the operation of modeling and closing.

If there are many working surfaces of die forgings and it is impossible to place them on the same side of the parting surface as the base surface, the processing base surface and most of the working surfaces should be on the same side of the parting surface. At the same time, the number of parting surfaces should be reduced as far as possible. It is better to have only one parting surface, which can simplify the operation process and improve the casting accuracy.

When choosing the parting surface of die forgings, the cavity and the main core should be in the lower shape as far as possible so as to facilitate the moulding, core setting, closing and inspection of the cavity size; but the lower cavity should not be too deep, and try to avoid the use of suspended cores and large suspended sand; at the same time, the flat and straight surface should be chosen as the parting surface and less curved surface should be used to simplify the moulding process and minimize the core and movable blocks. Quantity to simplify moulding, moulding, fitting and other processes.

In addition, the parting surface should be selected at the maximum cross section of the die forging to ensure that the pattern is taken out of the casting without damaging the casting. When selecting parting surface of castings, in order to ensure the quality of castings, it is necessary to avoid turning sand mould after closing. Generally, the pouring position should be determined first, and then the parting surface should be considered.

For die forgings with low quality requirements, the parting surface that can simplify the process should be selected first, and the selection of pouring position should be the same, and the corresponding requirements should be met to ensure that the whole die forging can achieve the corresponding high quality.

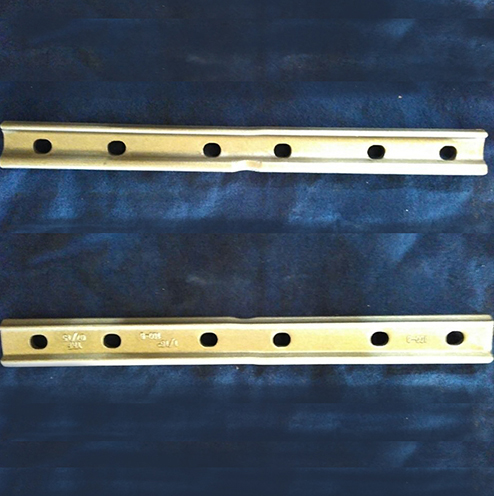

Die Forging Manufacturer, Truck Front Axle, Large Die Forging Selection Linyi Hongsen Rail Transit Material Co., Ltd.